Cutting Tool Relief Angle . The effective rake angle is the combination of the tool holder’s angle of inclination and the rake built into the insert. 9 rows this page give rake and relief angles for turning various materials with high speed steel tool bits. Functions of side clearance (relief) angle: (b) this angle varies from 0° to 15°, and usually 8°. Side and end relief angles: (c) excessive relief angle reduces strength of the tool. (a) it allows the tool to cut freely without rubbing against the work surface. Functions of end clearance (relief) angle: The back rake angle affects the chip thickness and the. To avoid the rubbing of the cutting tool with the work piece, a relief angle is provided as shown. This angle is known as the rake angle of the tool, or the back rake angle. The lead or entry angle is the. Relief angles are for the purpose of helping to eliminate tool breakage and to increase tool life.

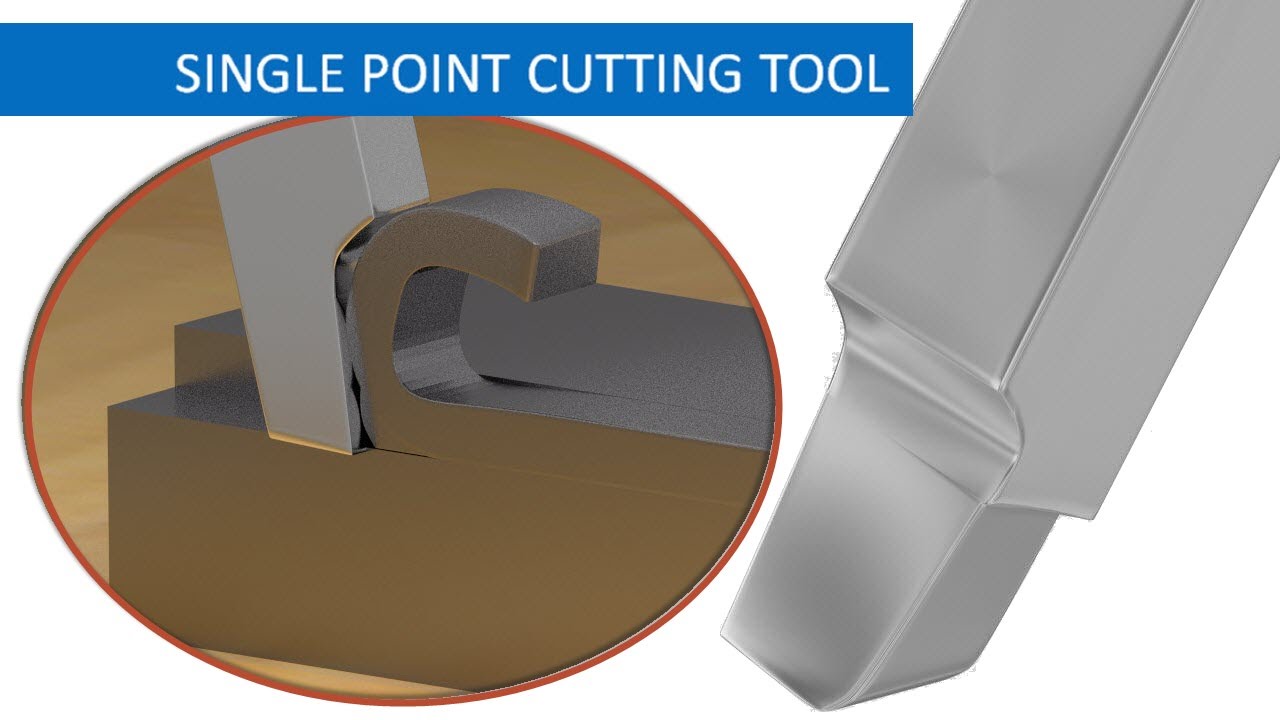

from www.youtube.com

(b) this angle varies from 0° to 15°, and usually 8°. To avoid the rubbing of the cutting tool with the work piece, a relief angle is provided as shown. Functions of side clearance (relief) angle: The lead or entry angle is the. Side and end relief angles: (c) excessive relief angle reduces strength of the tool. Relief angles are for the purpose of helping to eliminate tool breakage and to increase tool life. The back rake angle affects the chip thickness and the. This angle is known as the rake angle of the tool, or the back rake angle. 9 rows this page give rake and relief angles for turning various materials with high speed steel tool bits.

Understanding Cutting Tool Geometry YouTube

Cutting Tool Relief Angle (b) this angle varies from 0° to 15°, and usually 8°. The back rake angle affects the chip thickness and the. (c) excessive relief angle reduces strength of the tool. Side and end relief angles: This angle is known as the rake angle of the tool, or the back rake angle. 9 rows this page give rake and relief angles for turning various materials with high speed steel tool bits. The effective rake angle is the combination of the tool holder’s angle of inclination and the rake built into the insert. The lead or entry angle is the. Functions of end clearance (relief) angle: Relief angles are for the purpose of helping to eliminate tool breakage and to increase tool life. (b) this angle varies from 0° to 15°, and usually 8°. Functions of side clearance (relief) angle: To avoid the rubbing of the cutting tool with the work piece, a relief angle is provided as shown. (a) it allows the tool to cut freely without rubbing against the work surface.

From www.theengineerspost.com

Single Point Cutting Tool Diagram, Nomenclature, Material [PDF] Cutting Tool Relief Angle 9 rows this page give rake and relief angles for turning various materials with high speed steel tool bits. To avoid the rubbing of the cutting tool with the work piece, a relief angle is provided as shown. This angle is known as the rake angle of the tool, or the back rake angle. (b) this angle varies from 0°. Cutting Tool Relief Angle.

From www.mmc-carbide.com

End Mill Terminology Technical Info / Cutting Formula MITSUBISHI Cutting Tool Relief Angle Side and end relief angles: (a) it allows the tool to cut freely without rubbing against the work surface. Functions of side clearance (relief) angle: Functions of end clearance (relief) angle: The effective rake angle is the combination of the tool holder’s angle of inclination and the rake built into the insert. (b) this angle varies from 0° to 15°,. Cutting Tool Relief Angle.

From www.mech4study.com

Single Point Cutting Tool Nomenclature, Angle,Geometry and Signature Cutting Tool Relief Angle (c) excessive relief angle reduces strength of the tool. 9 rows this page give rake and relief angles for turning various materials with high speed steel tool bits. (b) this angle varies from 0° to 15°, and usually 8°. The back rake angle affects the chip thickness and the. To avoid the rubbing of the cutting tool with the work. Cutting Tool Relief Angle.

From learnmechanical.com

Single Point Cutting Tool Definition, Types, Geometry, Nomenclature Cutting Tool Relief Angle To avoid the rubbing of the cutting tool with the work piece, a relief angle is provided as shown. Functions of end clearance (relief) angle: (c) excessive relief angle reduces strength of the tool. (b) this angle varies from 0° to 15°, and usually 8°. The back rake angle affects the chip thickness and the. The lead or entry angle. Cutting Tool Relief Angle.

From www.green-mechanic.com

Green Mechanic Explain single point cutting tool geometry, angles and Cutting Tool Relief Angle Relief angles are for the purpose of helping to eliminate tool breakage and to increase tool life. The lead or entry angle is the. 9 rows this page give rake and relief angles for turning various materials with high speed steel tool bits. The back rake angle affects the chip thickness and the. (a) it allows the tool to cut. Cutting Tool Relief Angle.

From www.manufacturingguide.com

Turning tool angles Find suppliers, processes & material Cutting Tool Relief Angle The lead or entry angle is the. Functions of side clearance (relief) angle: The effective rake angle is the combination of the tool holder’s angle of inclination and the rake built into the insert. Functions of end clearance (relief) angle: (a) it allows the tool to cut freely without rubbing against the work surface. To avoid the rubbing of the. Cutting Tool Relief Angle.

From www.mech4study.com

Single Point Cutting Tool Nomenclature, Angle,Geometry and Signature Cutting Tool Relief Angle Functions of end clearance (relief) angle: The effective rake angle is the combination of the tool holder’s angle of inclination and the rake built into the insert. 9 rows this page give rake and relief angles for turning various materials with high speed steel tool bits. The lead or entry angle is the. This angle is known as the rake. Cutting Tool Relief Angle.

From www.mechanicalbooster.com

Single Point Cutting Tool Geometry, Angles, Nomenclature and Signature Cutting Tool Relief Angle To avoid the rubbing of the cutting tool with the work piece, a relief angle is provided as shown. (b) this angle varies from 0° to 15°, and usually 8°. Functions of side clearance (relief) angle: The back rake angle affects the chip thickness and the. This angle is known as the rake angle of the tool, or the back. Cutting Tool Relief Angle.

From huanatools.com

Positive Angle Inserts VS Negative Angle Inserts Huana Tools Cutting Tool Relief Angle The back rake angle affects the chip thickness and the. Functions of end clearance (relief) angle: (a) it allows the tool to cut freely without rubbing against the work surface. (b) this angle varies from 0° to 15°, and usually 8°. The effective rake angle is the combination of the tool holder’s angle of inclination and the rake built into. Cutting Tool Relief Angle.

From www.minaprem.com

What is Clearance Angle in Cutting Tool? Machining Principles Cutting Tool Relief Angle (c) excessive relief angle reduces strength of the tool. Relief angles are for the purpose of helping to eliminate tool breakage and to increase tool life. 9 rows this page give rake and relief angles for turning various materials with high speed steel tool bits. The back rake angle affects the chip thickness and the. Functions of side clearance (relief). Cutting Tool Relief Angle.

From www.mechanicalbooster.com

Single Point Cutting Tool Geometry, Angles, Nomenclature and Signature Cutting Tool Relief Angle (b) this angle varies from 0° to 15°, and usually 8°. To avoid the rubbing of the cutting tool with the work piece, a relief angle is provided as shown. Functions of end clearance (relief) angle: 9 rows this page give rake and relief angles for turning various materials with high speed steel tool bits. This angle is known as. Cutting Tool Relief Angle.

From www.youtube.com

DRILL BIT ANGLES (हिन्दी)l ड्रिल के कोण Drill Angles Types Of Drill Cutting Tool Relief Angle (b) this angle varies from 0° to 15°, and usually 8°. (c) excessive relief angle reduces strength of the tool. Functions of end clearance (relief) angle: To avoid the rubbing of the cutting tool with the work piece, a relief angle is provided as shown. This angle is known as the rake angle of the tool, or the back rake. Cutting Tool Relief Angle.

From www.youtube.com

single point cutting tool geometry Tool Signature Nomenclature of Cutting Tool Relief Angle The effective rake angle is the combination of the tool holder’s angle of inclination and the rake built into the insert. Functions of side clearance (relief) angle: Functions of end clearance (relief) angle: 9 rows this page give rake and relief angles for turning various materials with high speed steel tool bits. (a) it allows the tool to cut freely. Cutting Tool Relief Angle.

From www.regalcuttingtools.com

Which Drill Point Angle Should I Use? Regal Cutting Tools Cutting Tool Relief Angle Side and end relief angles: Relief angles are for the purpose of helping to eliminate tool breakage and to increase tool life. The lead or entry angle is the. To avoid the rubbing of the cutting tool with the work piece, a relief angle is provided as shown. The back rake angle affects the chip thickness and the. (b) this. Cutting Tool Relief Angle.

From 4mechtech.blogspot.com

Mechanical Technology Lathe Machine Cutting Tool Angles Cutting Tool Relief Angle Relief angles are for the purpose of helping to eliminate tool breakage and to increase tool life. The lead or entry angle is the. (c) excessive relief angle reduces strength of the tool. Side and end relief angles: This angle is known as the rake angle of the tool, or the back rake angle. To avoid the rubbing of the. Cutting Tool Relief Angle.

From www.machinemfg.com

Lathe Cutting Tool Angles Selection Principle MachineMFG Cutting Tool Relief Angle (c) excessive relief angle reduces strength of the tool. The lead or entry angle is the. Relief angles are for the purpose of helping to eliminate tool breakage and to increase tool life. The back rake angle affects the chip thickness and the. (b) this angle varies from 0° to 15°, and usually 8°. Functions of side clearance (relief) angle:. Cutting Tool Relief Angle.

From www.themachinedesign.com

Single Point Cutting Tool Tool Angles , Nomenclature, Geometry Cutting Tool Relief Angle Side and end relief angles: The effective rake angle is the combination of the tool holder’s angle of inclination and the rake built into the insert. To avoid the rubbing of the cutting tool with the work piece, a relief angle is provided as shown. The back rake angle affects the chip thickness and the. (a) it allows the tool. Cutting Tool Relief Angle.

From www.youtube.com

Single Point Cutting Tool Nomenclature, Tool Signature, Side Rake Cutting Tool Relief Angle The back rake angle affects the chip thickness and the. To avoid the rubbing of the cutting tool with the work piece, a relief angle is provided as shown. Relief angles are for the purpose of helping to eliminate tool breakage and to increase tool life. Side and end relief angles: The effective rake angle is the combination of the. Cutting Tool Relief Angle.